A great debate over plastic containers and bulging landfills is growing throughout the mobile food industry, to the point that some cities are discussing and creating laws that prohibited these vendors from using Styrofoam containers.

Because of this, Mobile Cuisine Magazine wanted to share with our readers some information based on a new product has slipped into the marketplace: Bioplastics.

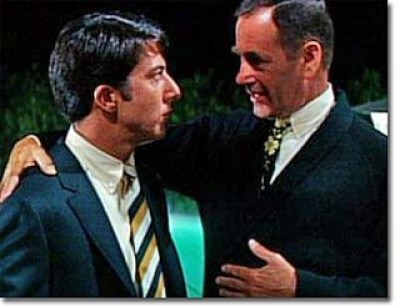

To take a dialog from the movie The Graduate, and make it fit better for this article we present…

To take a dialog from the movie The Graduate, and make it fit better for this article we present…

Mr. McGuire: I just want to say one word to you. Just one word.

Benjamin: Yes, sir.

Mr. McGuire: Are you listening?

Benjamin: Yes, I am.

Mr. McGuire: Bioplastics.

Benjamin: Exactly how do you mean?

Made from renewable, raw materials, including corn, wheat, potatoes, beets and a variety of other plants, bioplastics have been on the drawing board since the mid-1980s. They are often referred to as PLAs, or polylactic acid, because this is what the plant matter is ultimately converted into. They are available in the form of containers, dishes, utensils and “plastic” bags.

The Advantages of Bioplastics

- Producing bioplastics uses 65% less energy than it takes to produce petroleum-based plastics, making bioplastics the energy-efficient choice, hands down.

- Bioplastics generate 68% fewer greenhouse gases than fossil-fuel-based plastics. Clearly, they are better for the environment.

- Manufacturing petroleum-based plastics uses approximately 200,000 barrels of oil per day. Switching to bioplastics means being less dependent on foreign oil.

- As they degrade, bioplastics will remain non-toxic and will not leach dangerous chemicals into the soil. This means they are safer.

- The process of making bioplastics has finally become cost effective.

- Bioplastics can be recycled and this is always good news. In fact, certain grassroots recycling organizations are very excited by the prospect of bioplastics.

The Disadvantages

Despite the fact that bioplastics are a great improvement over fossil-based fuels, they are not yet the perfect solution. Here’s why:

- Most recycling centers are not set up to handle large amounts of PLA. Presently, PLA products cannot be recycled in conjunction with petroleum-based products, which means sorting is critical.

- Bioplastics are “compostable,” but only under specific conditions. To biodegrade within 90 days, as described, the products have to reach 140° F for 10 consecutive days. This requires a special facility, which few consumers have access to. If your PLA products end up at the landfill, they will not degrade any faster than a petroleum-based product.

- Planting corn for non-food uses is problematic for a number of reasons. Most corn planted for industrial uses is genetically modified, raising the question of the potential contamination of conventional crops. Soil erosion is another problem.

- Plant-based bioplastics have a low melting point. This means that if you leave a corn-based take-away container in your car on a warm day, when you return you might find that it has melted into a small puddle.

The Cost of Convenience

The problem of landfills overflowing with non-biodegradable plastic bags and containers is growing. Some cities are passing the cost of convenience on to the customer in the form of a “plas tax,” whereby consumers pay a fixed amount for plastic bags. Reportedly, this has resulted in a 90% drop in consumption in those areas. But not all municipalities are in agreement with this approach. Either way, the best solution is to think of disposables as a luxury. Use them sparingly and try to rely on re-usable products as much as possible.